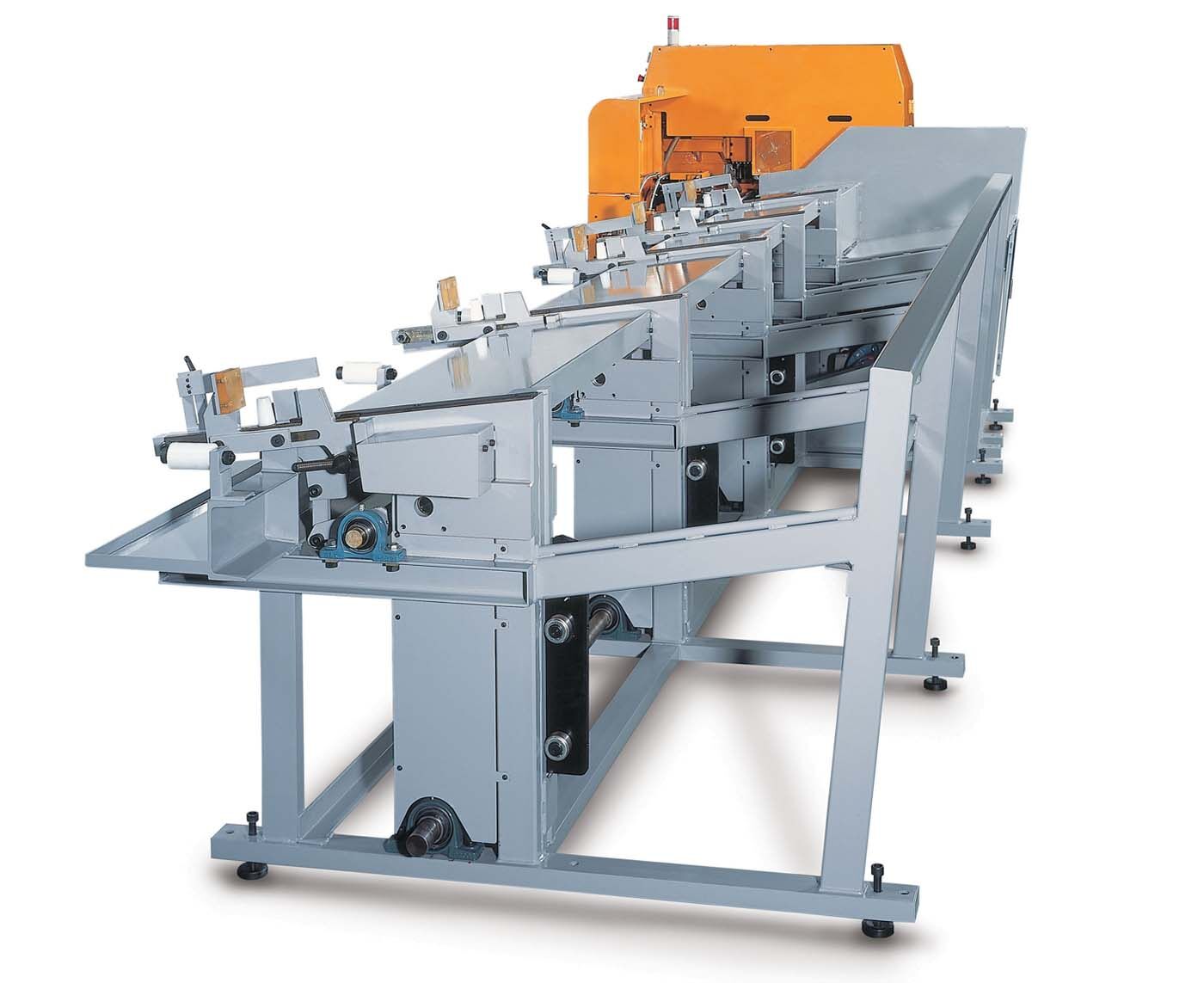

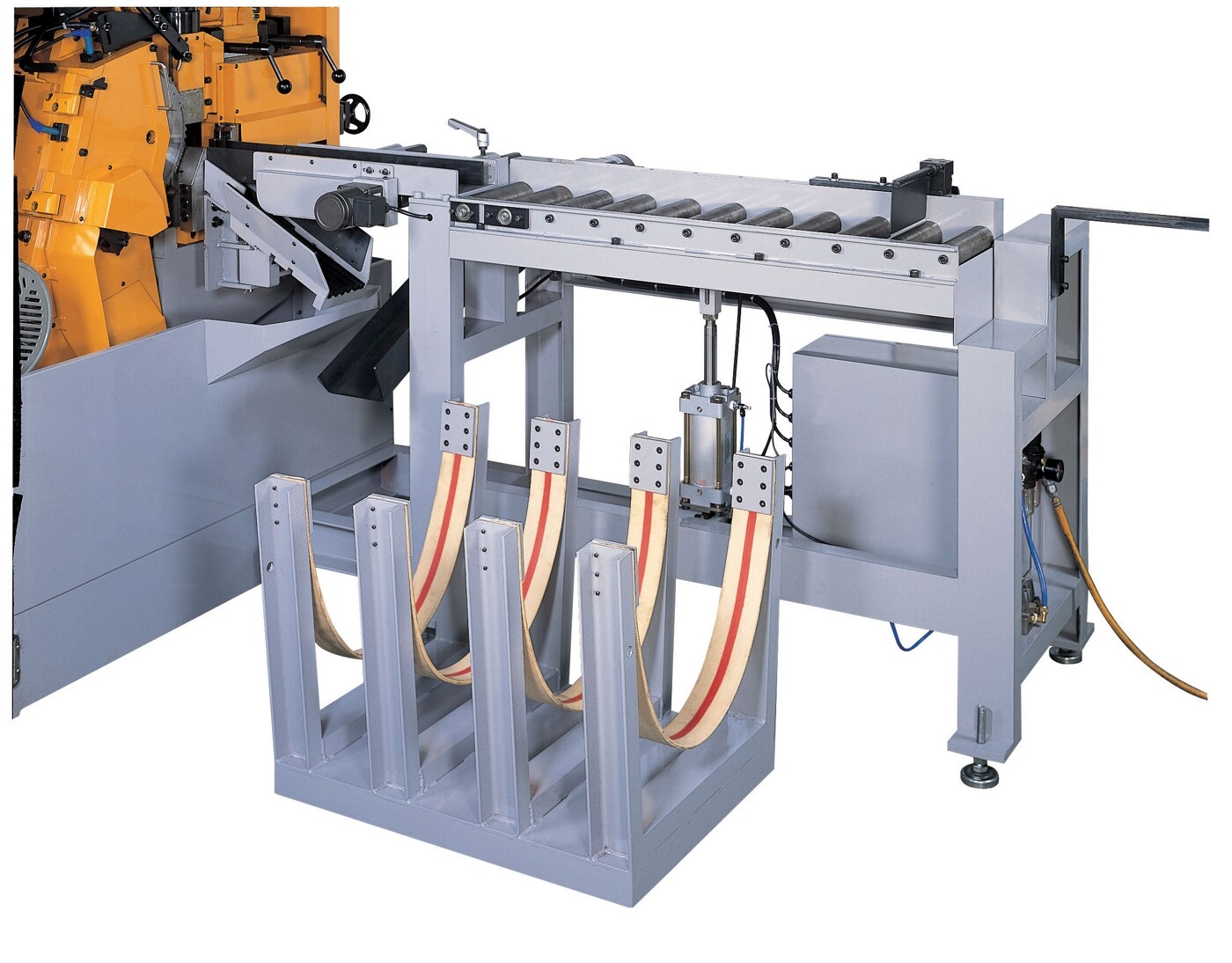

High Speed Circular Sawing Machine

- Home / Sawing Machines / Circular Sawing Machine for Metals / High Speed Circular Sawing Machine

|

|

|

|

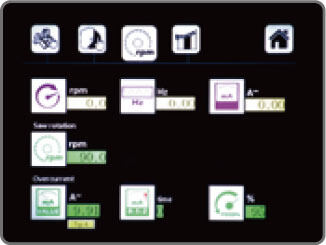

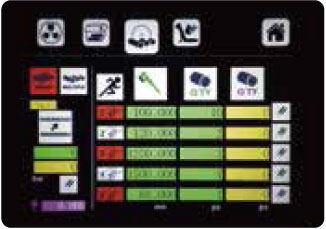

CNC Controlled with PLC Modular Unit POD (Programmable Operation Display) – 8.4″ color high-resolution Touch Sensing Screen |

|

Real Time Monitoring

|

|

Maintenance record

|

|

Servo Feed Saw Head

|

|

Tube Cutting

|

|

Blade Set up/ Cut-off Point

|

|

Multiple Lengths

|

| Cut-off Capacity | KTC-70EH | KTC-100EH |

|---|---|---|

| Round Bar ● | 8 ~ 70 mm / 0.314 ~ 2.275 in | 10 ~ 100 mm / 0.393 ~ 4.000 in |

| Square Bar ■ | 8 ~ 60 mm / 0.314 ~ 2.362 in | 10 ~ 85 mm / 0.393 ~ 3.346 in |

| Round Tube ○ | 8 ~ 70 mm / 0.314 ~ 2.275 in | 10 ~ 100 mm / 0.393 ~ 4.000 in |

| Square Tube □ | 8 ~ 60 mm / 0.314 ~ 2.362 in | 10 ~ 85 mm / 0.393 ~ 3.346 in |

| Saw Head & Spindle | KTC-70EH | KTC-100EH |

| TCT Carbide tipped sawblade | Ø285 x 2.0 t / Ø315 x 2.25 t mm | Ø360 x 2.6 t mm |

| HSS High-speed steel sawblade type | Ø325 x 2.0 t~3.0 t mm | Ø440 x 2.0 t ~ 4.0 t mm (Max.) |

| Sawblade rotation speed | 17 ~ 200 rpm | 20 ~ 180 rpm |

| Chip removal | Steel brush disk | |

| Motor | ||

| Spindle driving motor | 11.25 kw (15Hp) / 4p | 15kw (20Hp) / 4p |

| Hydraulic pump motor | 2.25 kw (3Hp) / 4p | |

| Ac servo motor / GFC | 1 kw | |

| AC servo motor / Saw head | 2 kw | |

| Coolant pump motor | 0.19 kw / 2p | |

| Hydraulic Device | ||

| Work driving pressure | 70 kg/cm2 (7 MPa) | |

| Tank Capacity | 90 liters / 23.78 gallons | |

| Pneumatic Device | ||

| Work operating pressure | 4 ~ 6 kg/cm2 (55 ~ 85 psi) | |

| Others | ||

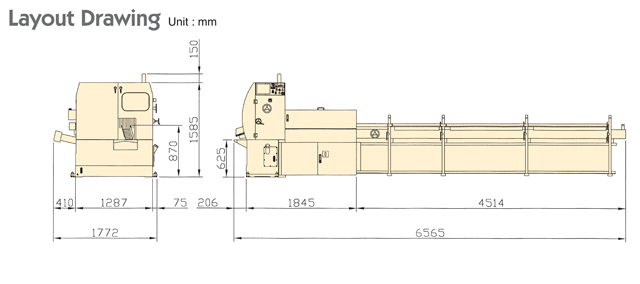

| Dimension (L x W x H) | 6570 x 1780 x 1740 mm / 6910 x 2530 x 1940 mm | |

| Weight | 2800 Kgs / 6173 lbs | 3000 Kgs / 6620 lbs |

* The specifications subject to change without prior notice.

No. 8, Lane 109, Renmei Road, Dali 41282, Taichung City, Taiwan

2022 © Kentai Machinery Co., LTD. All Rights Reserved.